Product

StepSERVO & Drive

StepSERVO Motor & Drive

DC Power +24V~+48V

Can be used in two ways: Open-Loop / Closed-Loop

Details

Closed loop control is possible using the StepSERVO Motor with a high-precision encoder.

1. System configuration diagram

|

2. Step SERVO application

| - 3D printer - Robot - Semiconductor equipment - Inspection equipment - Pharmaceutical industry | - Material transporter - Logistics equipment - Processing/logistics/inspection/measurement automation equipment - Small machine tools |

3. Step SERVO Features

- Uses DC 24V ~ 48V power

- Can be used in two ways: Open-Loop / Closed-Loop

- There is no step-out phenomenon as the current position is determined through the high-precision encoder mounted on the motor.

- Optimal position correction by always checking the current position with encoder feedback

- Easy gain adjustment provides optimal performance even under low rigidity loads

- Maximize motor efficiency by automatically adjusting current under load

- Improves equipment sensitivity and reliability by reducing heat loss by up to 80%

- Detection of overvoltage, overcurrent, overtemperature, and phase short

4. High-Speed Synchronous Control of Step Servo System

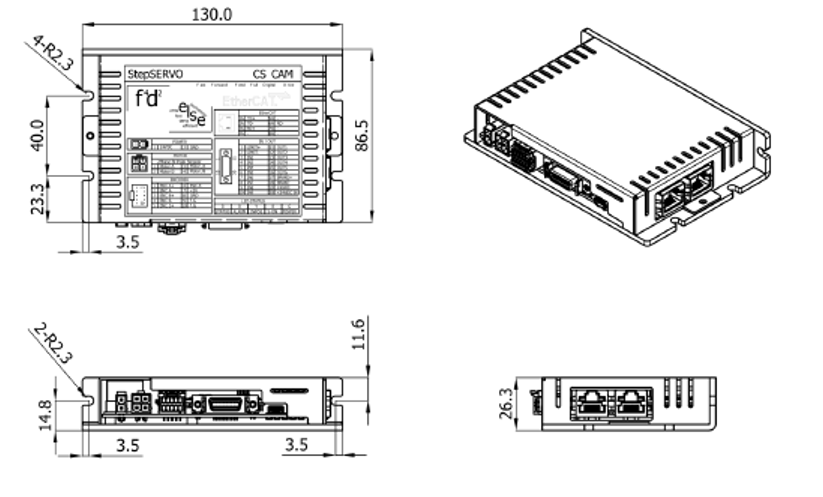

5. External dimension of Step SERVO drive

|

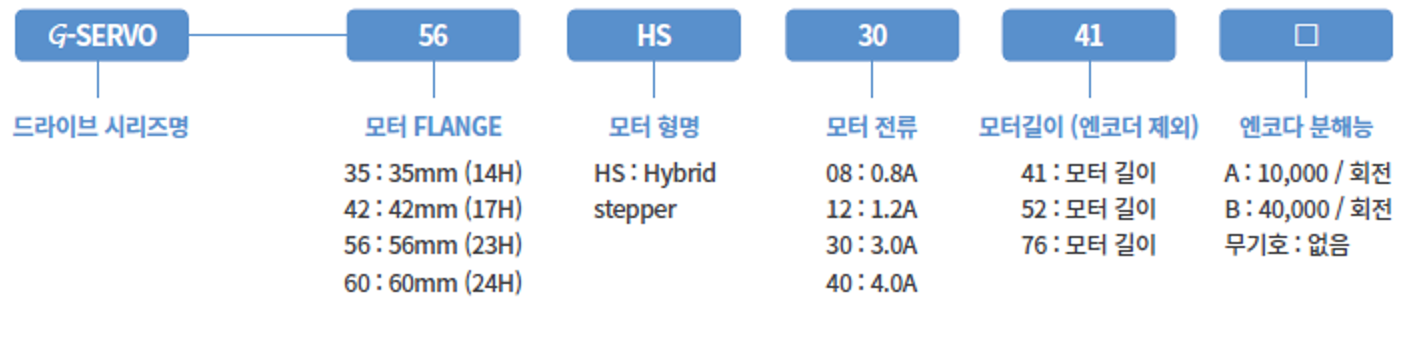

6. Step SERVO drive model number guide

|

| □ | Mortor | Length | Holding torque | Drive | |

| □ 35 | 35HS-0828A | 35HS-0828B | 28(46) | 0.16 Nm | G-SERVO-PULSE G-SERVO-MODBUS G-SERVO-ECAT |

| 35HS-0833A | 35HS-0833B | 33(51) | 0.2 Nm | ||

| 35HS-0836A | 35HS-0836B | 36(54) | 0.24 Nm | ||

□ 42 | 42HS-1235A | 42HS-1235B | 35(53) | 0.32 Nm | |

| 42HS-1241A | 42HS-1241B | 41(59) | 0.44 Nm | ||

| 42HS-1261A | 42HS-1261B | 61(79) | 0.65 Nm | ||

| □ 56 | 56HS-3041A | 56HS-3041B | 41(59) | 0.6 Nm | |

| 56HS-3052A | 56HS-3052B | 52(70) | 1.0 Nm | ||

| 56HS-3076A | 56HS-3076B | 76(94) | 1.5 Nm | ||

| □ 60 | 60HS-4045A | 60HS-4045B | 45(63) | 0.75 Nm | |

| 60HS-4056A | 60HS-4056B | 56(74) | 1.1 Nm | ||

| 60HS-4088A | 60HS-4088B | 88(106) | 2.7 Nm | ||

Specifications

Specification of Step SERVO drive

| Motor | □ 35mm | □ 42mm | □ 56mm | □ 60mm | |

| Drive type | G-SERVO-PULSE G-SERVO-MODBUS G-SERVO-ECAT | G-SERVO-PULSE G-SERVO-MODBUS G-SERVO-ECAT | G-SERVO-PULSE G-SERVO-MODBUS G-SERVO-ECAT | G-SERVO-PULSE G-SERVO-MODBUS G-SERVO-ECAT | |

| Input voltage | 24VDC ~ 48VDC ±10% | ||||

| Control method | Closed-Loop control, Open-Loop control, (ARM core + Motion controller) | ||||

| Power Consumption | Up to 600mA (excluding motor current) | ||||

| Usage environment | Temperature | Operation: 0 ~ 50℃, Storage: 0 ~ 70℃ | |||

| Humidity | Operation: 35 to 85%RH (no condensation), Storage: 10 to 90%RH (no condensation) | ||||

| Vibration | 0.5G | ||||

| 기 능 | Encoder | 10,000 / per revolution, 40,000 (option) / per revolution | |||

| Resolution | 1200, 1600, 2000, 3000, 5000, 9000, 10000, 20000, 40000 (SW Setting) | ||||

| RPM | Max. 3,000rpm | ||||

| Maximum input | 500kHz (Duty 50%) | ||||

| Protection function | Position tracking error, motor connection error, motor voltage error, input voltage error, overcurrent error, overload error, temperature error, motion controller temperature error | ||||

| Status display | Power, in-position, arlam | ||||

| In-position settings | SW setting (USB) | ||||

| Gain setting | |||||

| Electric gear ratio | |||||

| Pulse input method | 1 pulse (DIR / PULSE), 2 pulse (CW/CCW) settings (USB) | ||||

| Rotation direction setting | SW setting (USB) | ||||

| Speed/position command | 1 Pulse train (Differential) input (DIR/PULSE), (CW/CCW) | ||||

| I/O signal | Input signal | 1 Pulse train (Differential) input (DIR/PULSE), (CW/CCW) SERVO-on, ALARM-RESET: Insulation method using photocoupler | |||

| Output signal | In-position output, drive alarm output, encoder output (A+, A-, B+, B-, Z+, Z-) RS-422 line drive output | ||||

Download

| Division | File name | Download |

|---|